What's the best filter for ductless fume hood ?

2024-11-23 10:19:42

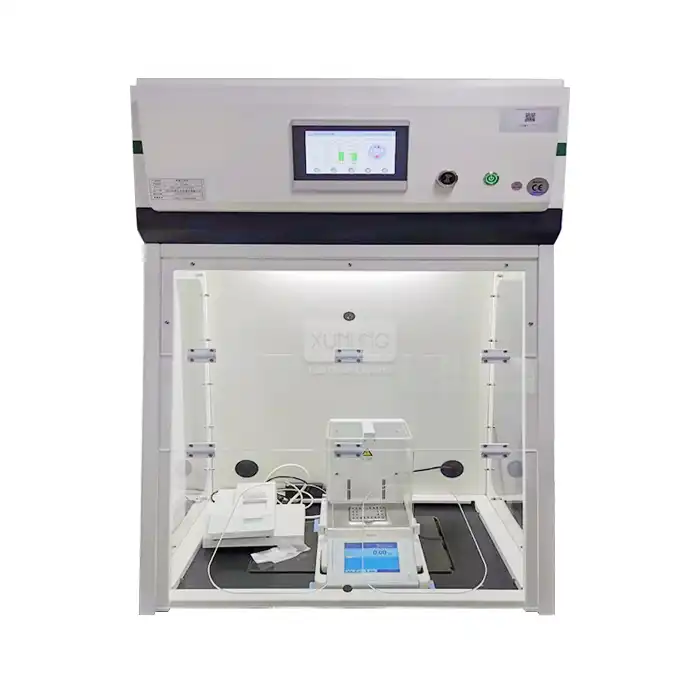

In the ductless ventilation equipment (Ductless fume hood, Filtered Storage Cabinet, PCR Workstations, Laminar Flow Hoods, Biosafety Cabinets etc), the filter is undoubtedly the most critical core part. When it comes to the removal of chemical gases, activated carbon filters have the highest comprehensive efficiency and become the first choice for various related equipment, we will tell you what is Activated carbon and how our filters are the best.

What is Activated carbon?

It has long been found that both mineral carbon (coal, bone carbon, etc.) or plant carbon (charcoal, coconut shell carbon, etc.) and the chemical carbon (coke, carbon black, etc.), all have a certain gas adsorption capacity. Especially Carbon with more pores on its surface can attracts more chemical gases.

A large number of micropores are formed on the surface of carbon materials by physical or chemical methods such as partial combustion and hot steaming. These micropores effectively enlarge the inner surface area required by chemical adsorption. The internal surface area of 1 kg activated carbon can reach 1 km2!

Surface structure of activated carbon before (left) and after (right) activation under microscope

The number and structure of micropores on the surface of activated carbon made from different carbon materials are also different. In a variety of activated carbon, the ones processed from plant carbon has more abundant microporous structure, among which coconut shell carbon is the best.

Coconut shell and Processed coconut shell activated carbon

How the Activated carbon adsorb ?

On the surface of activated carbon exists a lot of micropores, when the gas into the holes, the larger molecules or compounds of complicated structure will be captured and retained stably there. However, for some organic compounds of low molecular weight , (such as formaldehyde), inorganic gases (such as HNO3, H2SO4, HCl, etc.), ammonia (NH3) and amine compounds, the pure activated carbon can not do so well.

Why is our activated carbon filter the best?

Our activated carbon has been soaked by special chemical additives, these non-absorbable contaminations mentioned above will produce chemical reaction with additives attached to microporous of activated carbon, and finally form substances that can be adsorbed.

Many filter manufactures simply seal the carbons into a box, that leads to three problems, carbon leakage, uneven distribution, and through-through defect under the airflow continuous impact.

Xunling Technologies gas phase coconut shell carbon filters utilize our unique bonded carbon filtration media. This minimizes potentially hazardous carbon dust found in traditional granular carbon filters. Our proprietary bonding process holds carbon in a predictable matrix, preventing carbon shift that can lead to “dead spots” common in traditional granular filters.

YOU MAY LIKE

Control System_1734768462745.webp)