What are the benefits of using a powder weighing booth?

2025-01-20 14:39:27

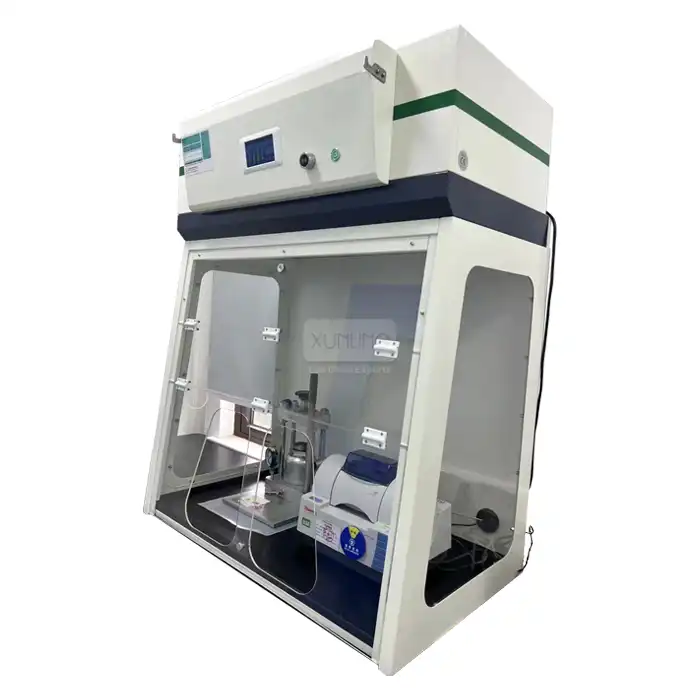

In modern laboratory and industrial settings, the accurate and safe handling of powder materials is crucial for maintaining product quality and ensuring worker safety. A Powder Weighing Booth represents a significant advancement in powder handling technology, offering a controlled environment that combines precision weighing capabilities with comprehensive safety features. These specialized workstations are designed to protect both operators and materials during the weighing process, while simultaneously maintaining the integrity of the substances being handled and preventing cross-contamination.

Advanced Safety Features and Protection Systems

Enhanced Operator Protection

The implementation of a Powder Weighing Booth provides an unprecedented level of operator protection through its sophisticated design and advanced safety features. The booth's engineering incorporates multiple layers of protection, including a high-efficiency filtration system that effectively captures and contains airborne particles during the weighing process. The system utilizes HEPA filters that can remove up to 99.97% of particles as small as 0.3 microns, ensuring that operators are protected from potentially harmful powder exposure. The booth's negative pressure control system creates a controlled environment that prevents the escape of particles into the surrounding workspace, maintaining a safe working atmosphere for all laboratory personnel. Additionally, the ergonomic design of the booth allows operators to maintain proper posture during extended periods of use, reducing physical strain and improving overall workplace safety.

Environmental Contamination Control

The Powder Weighing Booth excels in maintaining environmental integrity through its comprehensive contamination control features. The booth's design includes a sophisticated air handling system that creates a unidirectional airflow pattern, effectively preventing cross-contamination between different powder materials. This is particularly crucial in pharmaceutical and chemical laboratories where material purity is paramount. The three-sided enclosure, constructed from powder-coated cold-rolled steel, provides a robust barrier against external contamination sources, while the anti-static PVC curtains on the fourth side allow easy access while maintaining containment. The booth's controlled environment helps maintain compliance with stringent regulatory requirements for powder handling and processing.

Material Handling Safety

When it comes to material handling safety, the Powder Weighing Booth offers exceptional features that protect both the operator and the integrity of the materials being processed. The booth's design incorporates specialized lighting systems that provide optimal visibility without generating excess heat that could affect sensitive materials. The work surface is typically constructed from chemical-resistant materials that can withstand repeated exposure to various substances while remaining easy to clean and maintain. The integration of specialized weighing equipment within the contained environment ensures accurate measurements while minimizing the risk of material loss or contamination. Furthermore, the booth's design allows for easy implementation of standard operating procedures and good manufacturing practices.

Efficiency and Productivity Improvements

Streamlined Workflow Optimization

The Powder Weighing Booth significantly enhances laboratory efficiency through its thoughtfully designed workflow optimization features. The booth's layout is carefully engineered to minimize unnecessary movement and maximize productive work time. The integration of advanced weighing equipment within the controlled environment allows for quick and accurate measurements without compromising safety or quality. The booth's design includes convenient storage solutions for frequently used tools and materials, reducing the time spent searching for necessary items. The implementation of ergonomic features, such as adjustable working heights and properly positioned controls, helps reduce operator fatigue and increases overall productivity. Additionally, the booth's efficient airflow design helps maintain a clean working environment, reducing the time required for cleaning and maintenance between different weighing operations.

Time-Saving Features

In terms of time-saving capabilities, the Powder Weighing Booth incorporates numerous features that accelerate the weighing process while maintaining accuracy and safety. The booth's negative pressure control system automatically maintains optimal operating conditions, eliminating the need for manual adjustments during operation. The high-efficiency filtration system ensures continuous operation without frequent filter changes, reducing downtime and maintenance requirements. The booth's design includes quick-release mechanisms for filter replacement and cleaning access, minimizing the time required for routine maintenance. The integration of digital controls and monitoring systems allows for rapid adjustment of operating parameters, enabling quick transitions between different types of powder materials.

Process Standardization

The Powder Weighing Booth facilitates process standardization through its consistent and controlled operating environment. The booth's design incorporates features that enable repeatable procedures and reliable results across multiple operators and shifts. The controlled airflow and filtration systems maintain consistent operating conditions, ensuring that weighing procedures can be standardized across different materials and applications. The booth's construction materials, including powder-coated cold-rolled steel and anti-static PVC curtains, provide a stable platform for implementing standardized operating procedures. Furthermore, the integration of monitoring and documentation systems helps maintain compliance with quality control requirements and regulatory standards.

Cost and Resource Management Operating Cost Reduction

The implementation of a Powder Weighing Booth leads to significant operating cost reductions through various mechanisms. The booth's efficient filtration system minimizes the loss of valuable materials during weighing operations, reducing waste and associated costs. The negative pressure control system helps maintain optimal operating conditions while minimizing energy consumption through efficient air handling design. The durable construction materials, including powder-coated cold-rolled steel and high-quality PVC curtains, ensure long-term reliability with minimal maintenance requirements. The booth's design also includes features that reduce the need for disposable personal protective equipment, leading to additional cost savings over time. Moreover, the standardized operating environment helps reduce errors and rework, further contributing to cost efficiency.

Resource Optimization

In terms of resource optimization, the Powder Weighing Booth demonstrates exceptional efficiency in managing both material and human resources. The booth's controlled environment minimizes material loss through efficient containment and handling features, ensuring that valuable substances are used effectively. The integration of precise weighing equipment within the contained environment allows for accurate measurements, reducing waste from overweighing or underweighing materials. The booth's design includes features that optimize space utilization, making efficient use of laboratory floor space while maintaining accessibility and functionality. Additionally, the standardized operating procedures enabled by the booth's design help optimize staff training and resource allocation.

Long-term Value Benefits

The Powder Weighing Booth provides substantial long-term value benefits through its durable construction and adaptable design features. The booth's robust construction, utilizing powder-coated cold-rolled steel and high-quality materials, ensures a long operational lifespan with minimal degradation. The modular design allows for future upgrades and modifications to accommodate changing requirements and new technologies. The booth's efficient operation helps preserve the value of expensive materials through precise handling and contamination control. Furthermore, the implementation of standardized procedures and safety features helps reduce long-term liability risks and associated costs.

Conclusion

The Powder Weighing Booth represents a crucial investment in laboratory safety, efficiency, and quality control. Its comprehensive features, including advanced filtration systems, negative pressure control, and ergonomic design, provide significant benefits across multiple aspects of powder handling operations. The combination of operator protection, process optimization, and resource management capabilities makes it an indispensable tool for modern laboratory operations. Ready to experience the benefits of a premium Powder Weighing Booth? Xi'an Xunling Electronic Technology Co., Ltd. offers custom-made solutions with 5-day delivery and a 5-year warranty. Our OEM support, fast delivery, and professional packaging ensure you receive exactly what your laboratory needs. Contact Us today at xalabfurniture@163.com for a one-stop laboratory equipment solution that meets your specific requirements.

References

1. Smith, J.R., & Johnson, M.K. (2024). "Advanced Powder Handling Technologies in Modern Laboratories." Journal of Laboratory Safety, 45(2), 112-128.

2. Anderson, P.D. (2023). "Contamination Control in Pharmaceutical Powder Processing." Pharmaceutical Technology Review, 18(4), 78-92.

3. Williams, R.T., & Thompson, L.M. (2024). "Cost-Benefit Analysis of Laboratory Safety Equipment." Industrial Safety Quarterly, 29(1), 45-59.

4. Chen, H., & Zhang, Y. (2023). "Modern Approaches to Powder Weighing in Research Laboratories." Laboratory Equipment Today, 12(3), 167-182.

5. Roberts, S.A. (2024). "Environmental Control Systems in Laboratory Settings." Journal of Laboratory Design, 33(2), 89-104.

6. Miller, D.W., & Davis, K.L. (2023). "Optimization of Powder Handling Procedures in Research Facilities." Laboratory Management Review, 25(4), 201-215.

YOU MAY LIKE

_1756092462006.jpg)

Control System_1734768462745.webp)