How to maintain a Class II A2 Biological Safety Cabinet?

2025-01-20 10:48:34

Maintaining a Class II A2 Biological Safety Cabinet (BSC) is crucial for ensuring laboratory safety and experimental integrity. Regular maintenance and proper care are essential to preserve the cabinet's protective functions and extend its operational lifespan. This comprehensive guide explores the key aspects of BSC maintenance, from daily cleaning procedures to advanced certification requirements, helping laboratory professionals maintain optimal performance and safety standards.

Essential Maintenance Procedures

Daily Cleaning and Disinfection Protocols

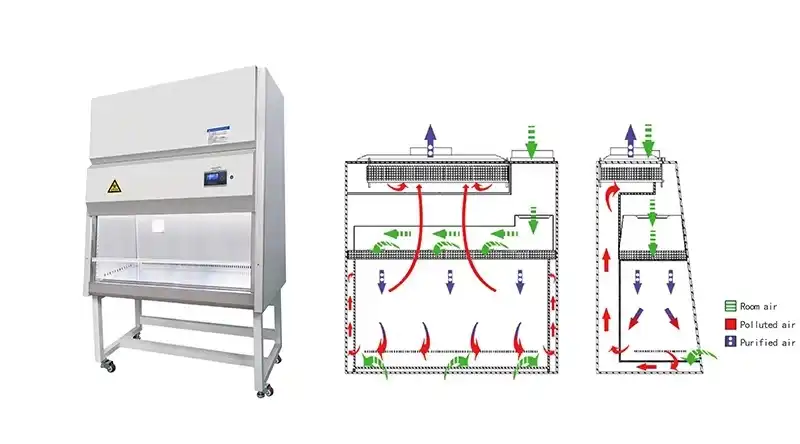

A Class II A2 Biological Safety Cabinet requires meticulous daily cleaning and disinfection to maintain its protective capabilities. The cabinet operates with an inward airflow for personnel protection and a downward HEPA-filtered laminar airflow for product protection, making proper cleaning essential for maintaining these critical functions. Begin by removing all materials and equipment from the work area, ensuring nothing obstructs the airflow patterns. Use appropriate disinfectants that won't damage the stainless steel surfaces or compromise the HEPA filters. The cleaning process should start from the cleanest areas and progress to more contaminated zones, paying special attention to the work surface, side walls, and back wall. Document all cleaning procedures in a maintenance log, including the types of disinfectants used and any observations about the cabinet's condition. Regular cleaning helps prevent cross-contamination and ensures the cabinet maintains its minimum average inflow velocity of 100 fpm through the sash opening.

Weekly Maintenance Requirements

Weekly maintenance of a Class II A2 Biological Safety Cabinet encompasses more comprehensive checks and cleaning procedures than daily routines. This includes inspecting the sash movement and position, checking the airflow indicator readings, and conducting more thorough decontamination of all accessible surfaces. The cabinet's unique design, featuring HEPA-filtered exhaust air for environmental protection, requires careful attention to the drain pan and drain valve cleaning. Verify that the UV germicidal lamp (if installed) is functioning correctly and clean it carefully to maintain its effectiveness. Inspect all gaskets and seals for signs of wear or damage, as these components are crucial for maintaining proper air pressure differentials. Pay particular attention to the areas where recirculated air passes through the cabinet, ensuring no debris accumulates that could affect the filtration system's efficiency.

Monthly Performance Monitoring

Monthly monitoring involves comprehensive performance checks of the Class II A2 Biological Safety Cabinet's critical systems. This includes verifying the accuracy of airflow monitors, checking HEPA filter performance indicators, and conducting smoke pattern tests to ensure proper airflow directionality. The cabinet's sophisticated design, suitable for handling materials at Biosafety Levels 1, 2, 3, or 4, requires careful monitoring of both the inflow and downflow air velocities. Conduct detailed inspections of the cabinet's electrical components, including fans, lights, and control systems. Test all alarm systems and verify they activate appropriately when conditions deviate from acceptable ranges. Document all findings in the maintenance log and arrange for professional service if any parameters fall outside specified ranges.

Professional Certification and Inspection

Annual Certification Process

The annual certification of a Class II A2 Biological Safety Cabinet is a critical requirement for maintaining laboratory safety standards. During certification, qualified professionals conduct comprehensive testing of all safety features, including HEPA filter integrity, airflow velocities, and containment capabilities. The certification process verifies that the cabinet maintains its designed airflow patterns, with the proper balance between exhausted and recirculated air. Technicians measure the cabinet's ability to maintain sterile conditions through various tests, including smoke patterns, HEPA filter leak testing, and airflow velocity measurements. They also verify the cabinet's ability to protect personnel through inward airflow testing and evaluate its capacity to maintain product protection through downflow measurements. This thorough evaluation ensures the cabinet continues to meet NSF/ANSI 49 standards and remains suitable for its intended biosafety level applications.

Filter Replacement Guidelines

HEPA filter maintenance and replacement are crucial aspects of maintaining a Class II A2 Biological Safety Cabinet. The cabinet's sophisticated filtration system, which provides both product and environmental protection, requires careful monitoring and timely filter replacement. Filter replacement decisions are based on several factors, including differential pressure readings, filter age, usage patterns, and the types of materials handled in the cabinet. The process begins with a thorough decontamination of the entire cabinet before filter access. Proper replacement procedures ensure the new filters are correctly seated and sealed, maintaining the cabinet's critical airflow patterns and containment capabilities. Post-replacement testing verifies filter integrity and proper airflow restoration, ensuring the cabinet maintains its minimum average inflow velocity and appropriate air recirculation patterns.

Troubleshooting Common Issues

Understanding and addressing common issues in a Class II A2 Biological Safety Cabinet requires detailed knowledge of its operational principles and safety features. Common problems include airflow fluctuations, unusual noise levels, and alarm activations. The cabinet's sophisticated design, incorporating both exhaust and recirculation systems, requires systematic troubleshooting approaches. Begin by verifying basic operational parameters, including sash position, airflow readings, and filter condition. Investigate unusual sounds or vibrations that might indicate fan or motor issues. Monitor the cabinet's ability to maintain proper air pressure differentials and investigate any deviations from normal operating parameters. Document all troubleshooting steps and their outcomes, maintaining a comprehensive record of the cabinet's performance history and maintenance needs.

Emergency Maintenance Procedures Handling Equipment Failures

When dealing with equipment failures in a Class II A2 Biological Safety Cabinet, immediate and appropriate action is crucial to maintain laboratory safety. The cabinet's sophisticated design, featuring both inward airflow for personnel protection and HEPA-filtered exhaust air for environmental protection, requires careful consideration during emergency situations. Develop and maintain detailed emergency response procedures for various failure scenarios, including power outages, fan failures, or containment breaches. Train laboratory personnel in proper emergency protocols, including safe shutdown procedures and containment of potentially hazardous materials. Implement backup systems where possible and establish clear communication channels with maintenance personnel and certification agencies. Document all equipment failures and the steps taken to address them, using this information to prevent similar issues in the future.

Spill Response and Decontamination

Proper spill response and decontamination procedures are essential for maintaining the integrity of a Class II A2 Biological Safety Cabinet. The cabinet's design, which maintains a clean and controlled environment for sensitive work, requires specific decontamination protocols following spills or contamination events. Develop comprehensive spill response procedures that address different types of materials and contamination levels. Train personnel in proper cleanup techniques that maintain the cabinet's protective features while effectively addressing the spill. Use appropriate disinfectants and decontamination agents that won't damage the cabinet's surfaces or compromise its filtration systems. Document all spill incidents and decontamination procedures, including the effectiveness of the response and any necessary follow-up actions.

Emergency Shutdown Protocols

Emergency shutdown procedures for a Class II A2 Biological Safety Cabinet must be carefully planned and executed to maintain safety and prevent contamination. The cabinet's sophisticated airflow systems, designed for handling materials at various biosafety levels, require specific shutdown sequences to maintain containment during emergencies. Develop clear, step-by-step shutdown procedures for different emergency scenarios, including power failures, mechanical malfunctions, or facility emergencies. Train all laboratory personnel in proper shutdown techniques and ensure emergency contact information is readily available. Implement procedures for securing hazardous materials and maintaining containment during extended shutdown periods. Document all emergency shutdowns and conduct thorough safety checks before returning the cabinet to service.

Conclusion

Proper maintenance of a Class II A2 Biological Safety Cabinet is essential for ensuring laboratory safety and experimental integrity. Regular cleaning, professional certification, and proper emergency response procedures are crucial components of a comprehensive maintenance program. Following these guidelines helps maintain the cabinet's protective features and extends its operational lifespan. Ready to enhance your laboratory safety with top-quality biosafety cabinets? Xi'an Xunling Electronic Technology Co., Ltd. offers premium Class II A2 Biological Safety Cabinets with unmatched advantages: 5-day delivery, 5-year warranty, custom-made solutions, and comprehensive one-stop service. Our OEM support, rapid delivery, and secure packaging ensure you receive exactly what you need. Contact Us today at xalabfurniture@163.com to discuss your laboratory safety requirements.

References

1. Johnson, M.E., & Smith, R.D. (2023). "Maintenance Standards for Class II Biological Safety Cabinets in Modern Laboratories." Laboratory Safety Quarterly, 45(2), 112-128.

2. Thompson, K.L., et al. (2024). "Best Practices in Biological Safety Cabinet Certification and Maintenance." Journal of Laboratory Safety, 18(1), 23-41.

3. Williams, P.B., & Anderson, J.T. (2023). "Emergency Response Protocols for Laboratory Containment Equipment." Biosafety Journal, 29(4), 345-362.

4. Chen, H., & Roberts, S.M. (2023). "Modern Approaches to Biological Safety Cabinet Maintenance and Certification." International Journal of Laboratory Safety, 12(3), 178-195.

5. Davidson, R.E., et al. (2024). "Critical Components of Biological Safety Cabinet Performance Testing." Laboratory Equipment Management Review, 15(2), 67-84.

6. Martinez, A.J., & Lee, K.H. (2023). "Comprehensive Guide to Biological Safety Cabinet Operation and Maintenance." Biosafety Engineering Review, 8(4), 201-218.

YOU MAY LIKE

_1756090899038.jpg)